-

Karnataka German

Technical Training Institute -

-

Manufacturing Technology

Manufacturing Technology

Most of the automated production systems make use of CNC applications. CAD / CAM is distinguished by the fact that it includes not only the manufacturing operations but also the design and planning functions that precede manufacturing. With the CAD software the designing professionals are offered large number of tools that help in carrying out thorough engineering analysis of design, manufacturing process and the manufactured components.

Why choose this

In the era of rapid industrialization particularly in the engineering field, there is a high requirement of specialized courses in CNC and CAD / CAM technologies.

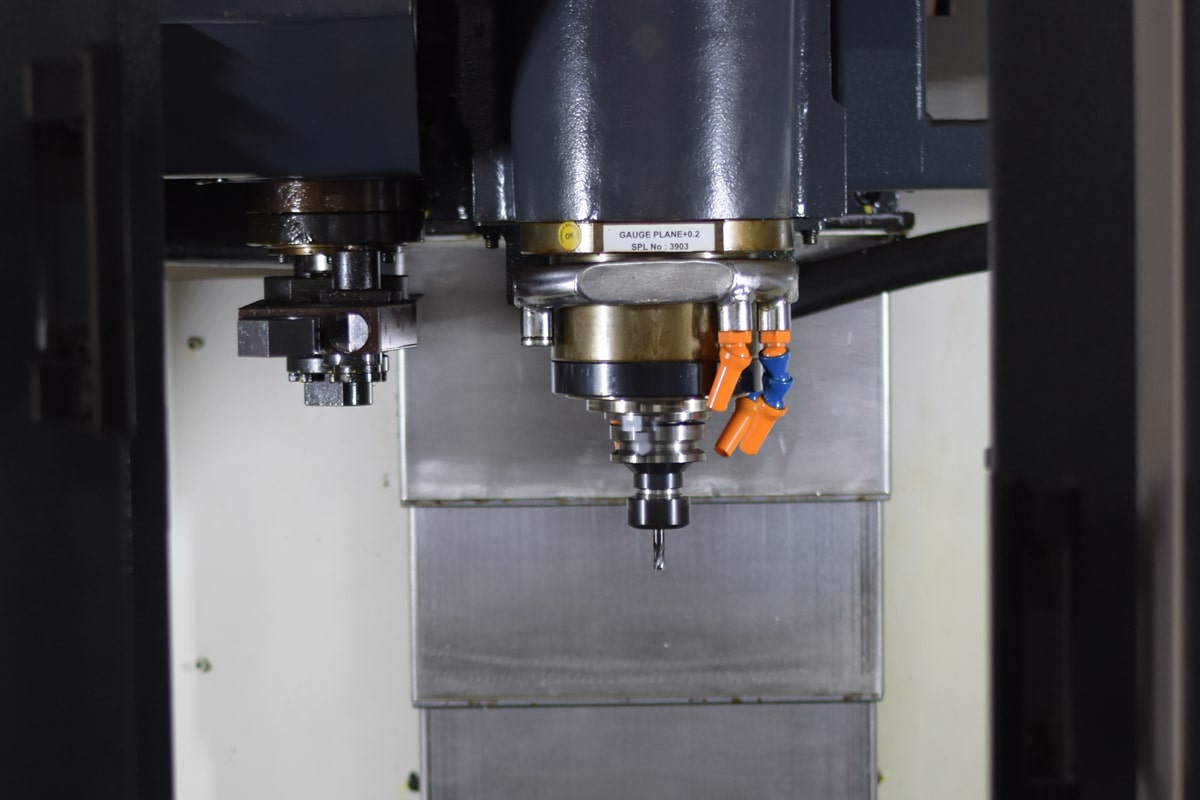

With the advent of advanced technologies, the Computerized Numerically Controlled (CNC) machines are rapidly replacing the older conventional production machines. They leverage ease of setting, operation, repeatability and accuracy. They are also capable of handling the latest cutting tools and apply the most modern manufacturing processes. The parts can be designed and the required tools paths, set-up sheet, process sheet generated using the CAD / CAM process. The resulting CNC program can be uploaded to the machine. On validating the prototyping process, bulk production can be undertaken with occasional supervision of the operator.

CNC Simulators are used for verifications of CNC programs and tool paths generated. They support Milling, Turning, Mill / Turn applications with full machine simulation and stock removal verifications. They can also identify problem areas such as potential collision, gouges or over travel and allow correction prior to NC code generation.

It is a technology concerned with the use of computers to perform complicated designs and manufacturing functions with ease and accuracy.

A CAM system is a software program that runs on a computer (commonly a Personal Computer) that helps the CNC programmer with the programming process It takes away the tediousness and drudgery out of programming.

OPPORTUNITIES

There is a very limited availability of technically skilled personnel having hands-on exposure to programming and operation of the state-of-the-art CNC machines and CNC programming software.

The students of KGTTI, who are trained to operate these machines and software can be highly sought after by the industry as (to name a few positions):

CNC Operator

Application Engineer - CAM

Application Engineer - CAD

Draughtsman

CNC Programmers

Shift in-Charges - CNC Shop

| Course Title | Course Duration | Months | Minimum Eligibility | Bengaluru | Kalaburagi | Belagavi | Mangaluru | Hubballi |

|---|---|---|---|---|---|---|---|---|

| CNC Programming and Operation - Turning | 80 Hours | 2 Months | BE/Diploma/ITI | √ | √ | √ | x | x |

| CNC Programming and Operation - Milling | 80 Hours | 2 Months | BE/Diploma/ITI | √ | √ | √ | x | x |

| CNC Machinist - Turning and Milling | 160 Hours | 4 Months | BE/Diploma/ITI | √ | √ | √ | x | x |

| Catia | 80 Hours | 2 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| Creo | 80 Hours | 2 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| Unigraphics | 80 Hours | 1 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| Solid Works | 80 Hours | 1 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| AutoCAD | 80 Hours | 1 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| MasterCAM | 80 Hours | 1 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| Basic Metrology | 80 Hours | 1 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| Advance Metrology | 80 Hours | 1 Months | BE/Diploma/ITI | √ | √ | x | x | x |

| Ansys | 120 Hours | 2 Months | BE/Diploma/ITI | √ | √ | x | x | x |