-

Karnataka German

Technical Training Institute -

-

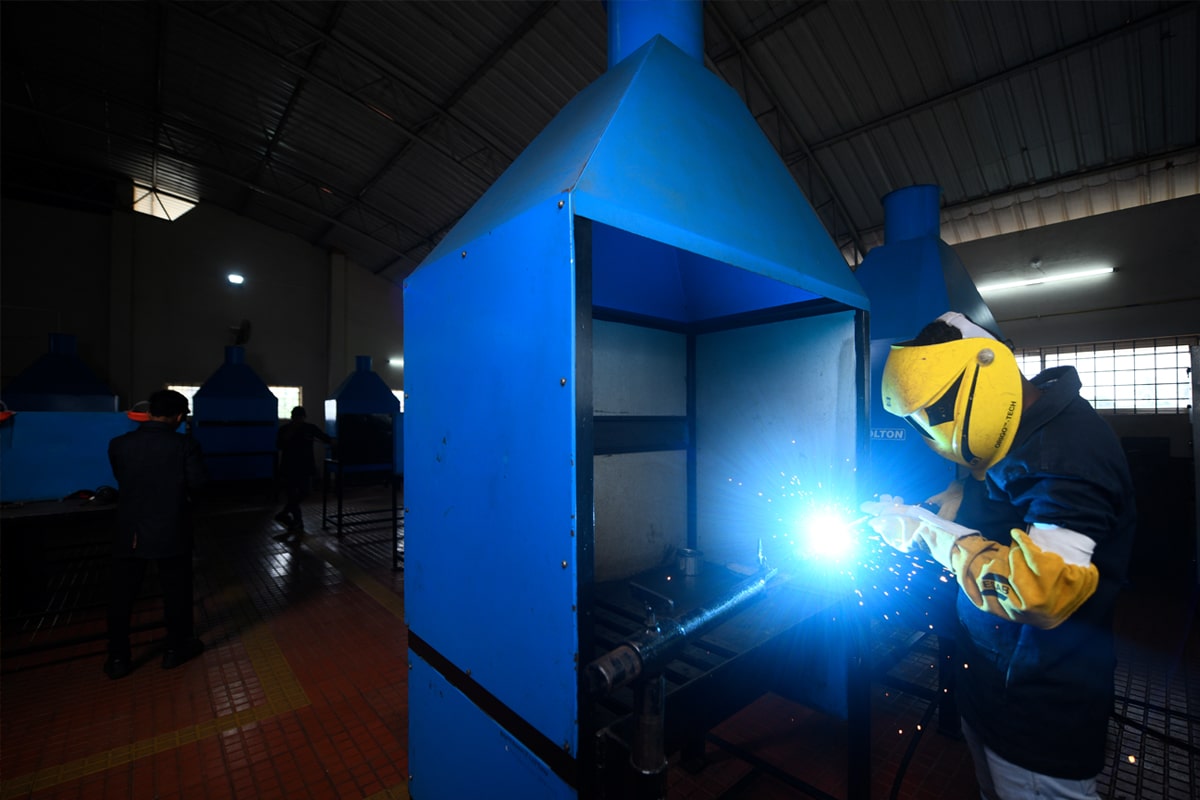

Welding Technology

Welding Technology

The welding programs at Karnataka German Technical Training Institute (KGTTI) are designed to meet the expanding needs of industries that utilize welding. The Institute is equipped with excellent infrastructure along with the state-of-the-art Welding Simulator to expose students to various courses in welding technologies. KGTTI adopts industry ready technologies with a view to bridge the gap between the academics and the industry.

Why choose this

In the era of rapid industrialization, particularly in the engineering field, there

is a high requirement of specialised courses. The various courses offered by KGTTI

in welding and other technologies that are oriented towards fulfilling the

requirements of the industry by providing skilled manpower.

Welding is a widely used skill, offering careers in fabrication and

construction industries as well as for self-employment in small scale enterprises

Most of the construction and infrastructure projects implemented today make use of

different welding technologies in various applications A few of the welding

technologies widely used in the industry are mentioned below:

Also known as Manual Metal Arc Welding (MMAW), SMAW is one of the world's most popular welding process which is considered as the mother of all welding processes. It uses a consumable flux covered electrode to weld metals such as carbon steels, HSLA steels, Cast Iron, Stainless Steel and their Alloys. SMAW is predominantly used in construction, maintenance and in fabrications.

Also known as Tungsten Inert Gas welding (TIG), it is an art welding process that normally uses a non-consumable tungsten electrode, with the help of a Shielding Gas (ARGON, HELIUM, NITROGEN) and a filler metal. The process can be used to weld metals such as Aluminium, magnesium, Copper, Stainless Steel, Nickel, Inconel, Carbon Steels, Jethethe and their alloys. The process is widely used in Aircraft industries to join thin gauge metals. It provides the operator with greater control over the weld to achieve stronger, higher quality welds.

The process is also known as Metal Inert Gas Welding (MIG) or Metal Active Gas Welding (MAG), this process uses bare electrode as a consumable with an envelope of shielding gas (Carbon Dioxide, Argon and Helium). The process is suitable for welding both thin and thick gauge materials. The process is suitable to weld metals like Carbon and Alloy steels, Aluminium alloys, Stainless Steel, Copper and Nickel alloys etc. GMAW is the fastest welding process which is employed in robotic, automatic and semi-automatic welding processes for having stronger and quality welds. It is extensively used in manufacturing of pressure vessels, automobiles and ship building industries.

This is a gas cutting process which requires a supporting gas (Oxygen) and fuel gases like (Acetylene, Hydrogen, LPG etc.). The gas cylinders are fitted with regulators, safety flash back arrestors and cutting torch. Oxy-acetylene cutting process is widely used in manufacturing and construction companies to make circle, profile and straight cuttings for thin and thick materials. It is also used in manual and automatic programmed cutting machines (PUG), with neat and quality cuttings.

It is one of the fastest, advanced and widely used cutting processes in many industries. The process requires a cutting torch; control unit, cooling water, one or more cutting gases (ARGON, NITROGEN, HELIUM, AIR, HYDROGEN or their MIXTURES). It is fast and is suitable for manual, automatic and robotic machine controlled cuttings to cut different metals such as Copper, Aluminum, Carbon steels and Stainless Steels. This process employs pilot arc system wherein good quality cutting in all provides and straight cutting of different thickness easily possible.

Pipe welding is highly sought after skill used in

manufacturing construction and fabrications industries.

Pipes are used by us in day to day life. They are also

used to build robust structures and in oil and gas lines

both or ground and under the sea.

Substantial exposure to SMAW / MMAW, GTAW and GMAW

welding processes is required to carry out good and

radiography quality pipe welding in different positions

(like 1G, 2G, 5G, 6G, 6GR)

| Course Title | Course Duration | Months | Minimum Eligibility | Bengaluru | Kalaburagi | Belagavi | Mangaluru | Hubballi |

|---|---|---|---|---|---|---|---|---|

| Gas Welding and Cutting | 180 Hours | 1 1/2 Months | 8th Pass/SSLC | √ | √ | x | √ | x |

| Shield Metal Arc Welding (SMAW) | 400 Hours | 3 Months | 8th Pass/SSLC | √ | √ | x | √ | x |

| Gas Tungsten Arc Welding (GTAW) | 180 Hours | 1 1/2 Months | SMAW / ITI Welder | √ | √ | x | √ | x |

| Gas Metal Arc Welding (GMAW) | 180 Hours | 1 1/2 Months | SMAW / ITI Welder | √ | √ | x | √ | x |

| Pipe Welding (6G) | 180 Hours | 1 1/2 Months | SMAW / ITI Welder | √ | √ | x | √ | x |

| Welding Technician (with TUV Certification) | 240 Hours | 3 Months | 8th Pass/SSLC | √ | √ | x | √ | x |